If it’s right in here, it’ll be right out there.

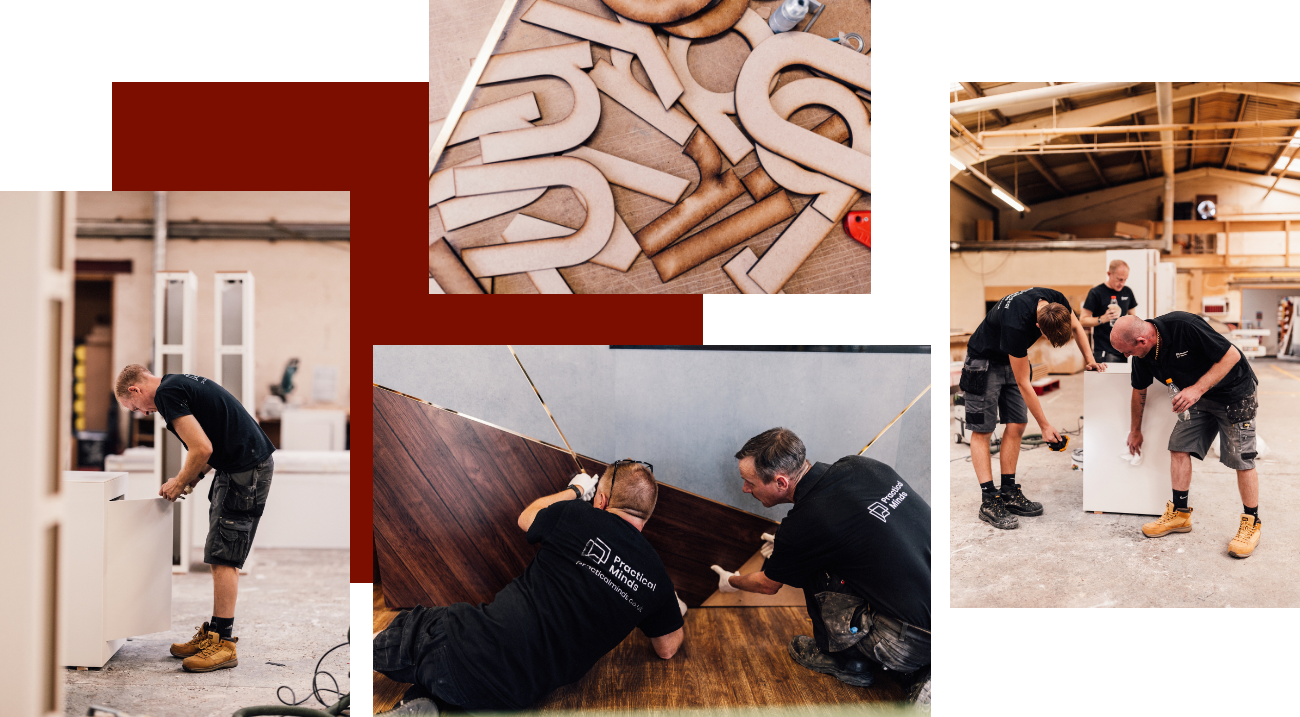

There are hundreds of manufacturers you could choose from, but no other has problem solving in its DNA quite like Practical Minds. Much like our design and print functions, our manufacturing arm is all about finding the right solution for the brief, this may involve joinery, acrylic fabrication, spray, scenic artistry, 3D printing, heat bending or laser cutting – we love the projects that others fear, the challenge is what makes us tick.

Quality and process underpin the excellent standard of work we produce, and our people are our greatest asset – we have lots of fantastic machinery and material expertise – but our dedicated team are the ones that make it happen every time for some of the worlds biggest and most demanding brands.

Quality Counts

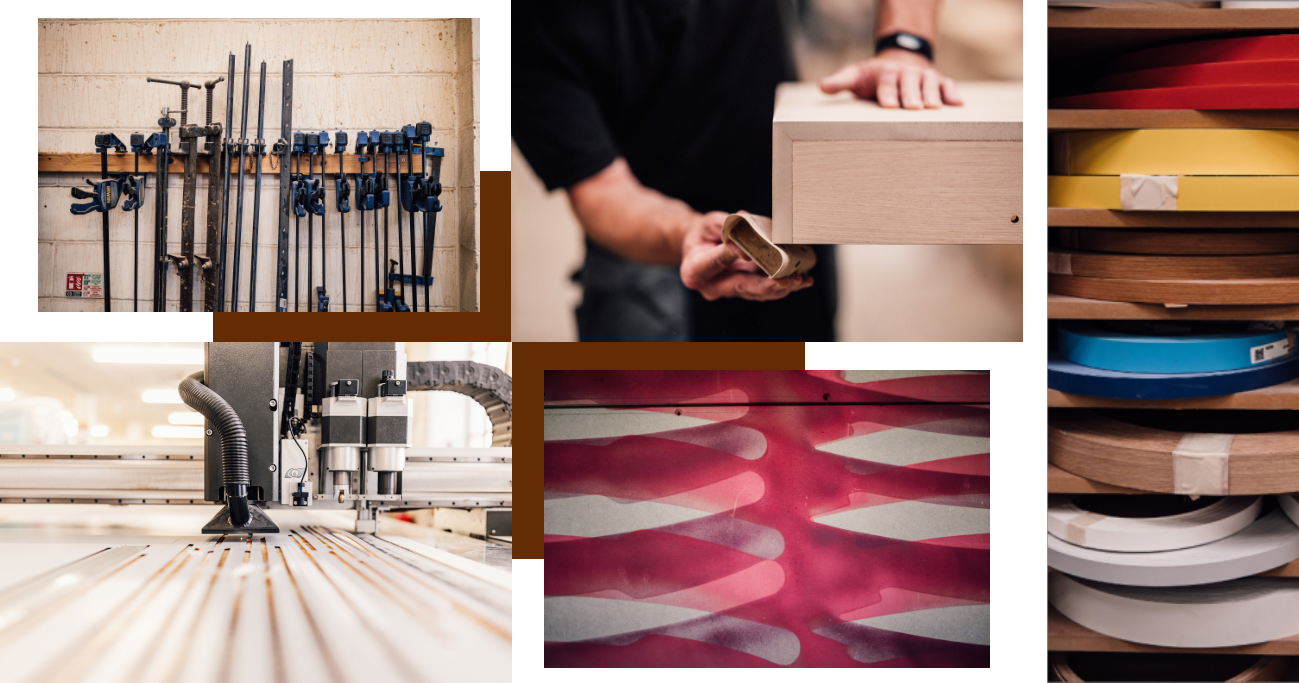

We have always tried to keep the challenge in-house, we have some outstanding partners to support – but if we can do it ourselves and control the quality then we are at our happiest. Some of our equipment used by our skilled workshop operatives include: CNC cutters, Laser cutting for timber and plastics, print, automated edge banding, laminating and solid surface services, heat bending, diamond polishing, two spray shops, vacuum forming, and Forty (yes 4-0!) 3D printers!

Our professional and courteous installation team are skilled in all manner of executions – whilst our talented project management team seamlessly process your brief, create time lines, and do all booking in alongside risk and method statements.

Who We Do It For

Every sector catered for

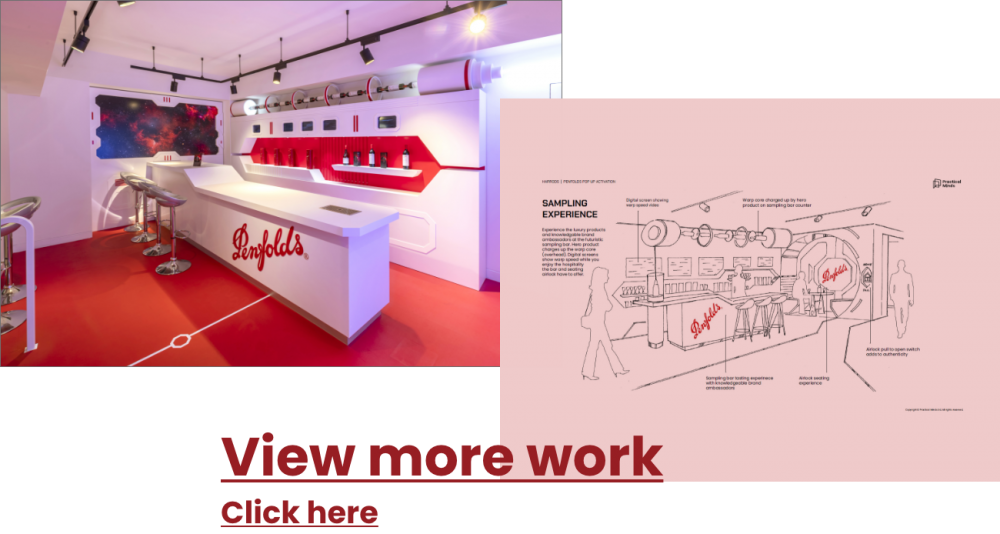

Practical Minds have a wealth of experience creating window displays, pop-up shops and concessions, mid mall displays, exhibitions, full shop fits, retail furniture POS, POP and really everything inbetween! We have specialisms in Luxury sectors such Jewellery, Watches and Fashion, Sporting goods, Cosmetics, Consumer electronics, FMCG and Food and Beverage.

Please get in touch with us today to receive the manufacturing support your brand deserves.